Fireclay Acid Brick

Fireclay bricks are preferred in areas exposed to high temperatures such as gas inlets on absorber towers. Fireclay bricks are less brittle and have better thermal shock resistance than red shale bricks. The alumina content of fireclay brick is higher which gives it more refractory properties.

Fire Clay Bricks are offered in two types and available in a variety of shapes (straights, arches, wedges, keys) and sizes:

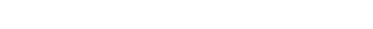

Alpha-Corr Type III Fireclay acid brick

For use where minimum absorption and maximum acid resistance are required.

Meets ASTM C279 for use in new construction and refurbishment of existing structures in sulphuric acid plants including towers, process vessels, floors, sumps, pits, etc

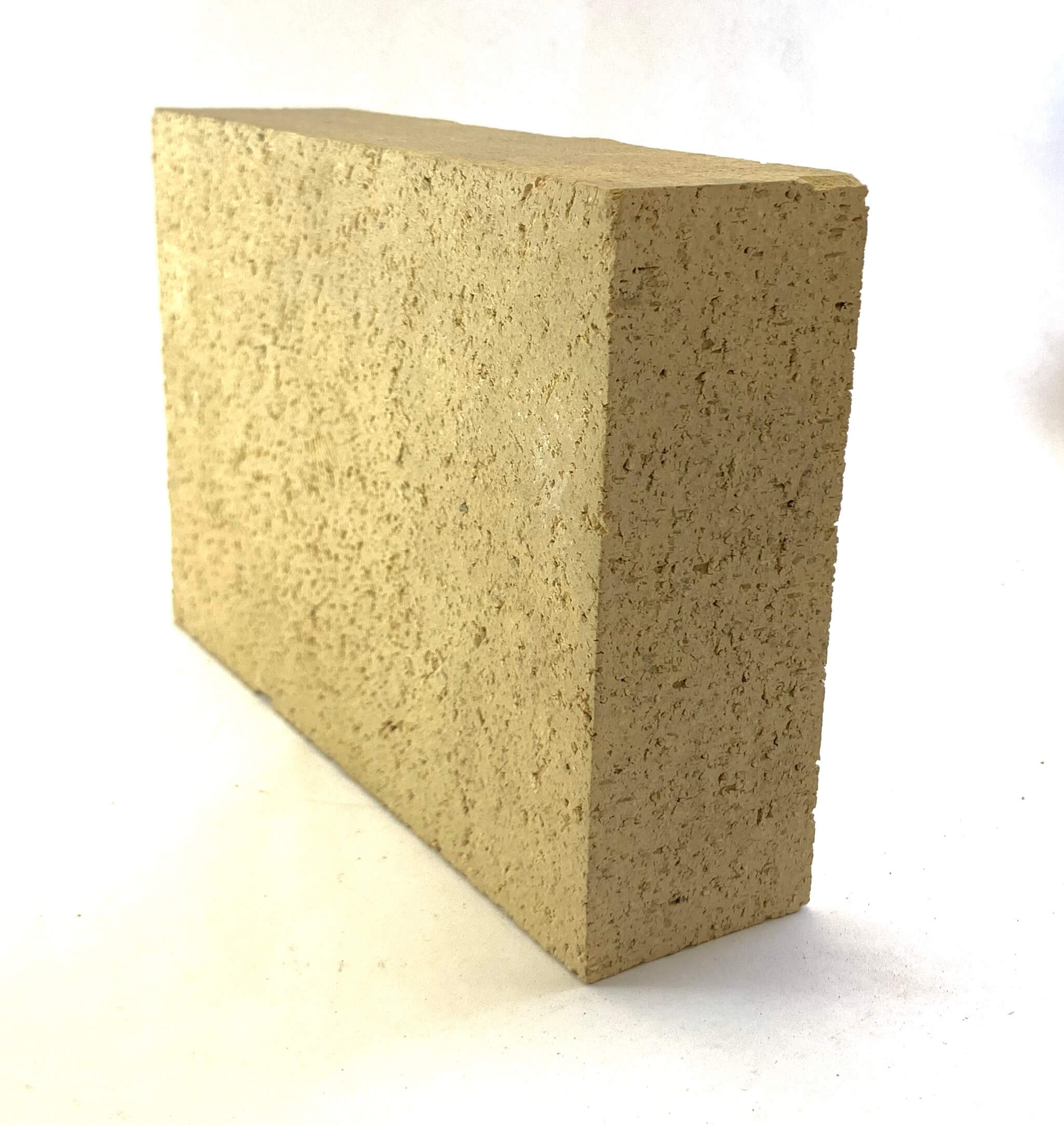

Belden Type II Fireclay acid bricks –

For use where lower absorption and higher acid resistance are required.

Type II Fireclay Bricks are supplied to us by the Belden Brick Co.

“Belden chemical resistant brick, backed by more than 135 years of brick making experience, are manufactured of specialty selected American shales and fire clays. These are fine-ground and specifically formulated for density and strength and fired at over 2000°F. This process results in brick that resists virtually all corrosive liquids and gases, except for acid fluorides and strong hot caustics” (htt)

(n.d.). Retrieved from https://www.beldenbrick.com/chemical-resistant-brick

Enter the details to be in contact with a representative